Thermal actuators with pulling action, for fire dampers, operated by thermal bulb

These mechanical thermal actuators are intended to close the fire dampers used on the ventilation ducts. Their large operating force unlocks the spring actuating the damper. Requiring no power supply, these devices are particularly simple and reliable. They are mandatory for all fire dampers to meet the NF-S 61.937 standard. Since thermal bulbs are not subject to creep, their periodic replacement is not necessary.

These mechanical thermal actuators are intended to close the fire dampers used on the ventilation ducts. Their large operating force unlocks the spring actuating the damper. Requiring no power supply, these devices are particularly simple and reliable. They are mandatory for all fire dampers to meet the NF-S 61.937 standard. Since thermal bulbs are not subject to creep, their periodic replacement is not necessary.

Straight length (A) of the actuating rod before release: 30mm or 25mm

Stroke of the actuating rod when triggering: ≥ 20 mm

Traction force of the actuating rod: ≥ 15 DaN (at the beginning of the stroke).

Orientation of the actuating rod bending: Aligned with the axis of the fixing screw. Other possible orientations: every 15° angular (MOQ apply) Communication with the external environment: The mechanisms are equipped with a low leakage wall, separating the air of the ventilation duct from that of the external environment.

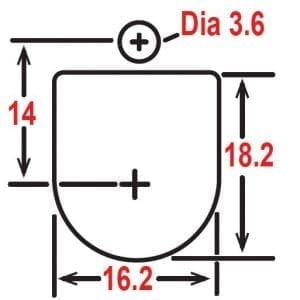

Installation: Through the wall of the ventilation duct, with M4 screws or self-tapping screws of similar dimensions. See the metal sheet cutting drawing below.

| Mounting hole dimensions (mm) |

|

Body material: PA66 glass fiber reinforced, withstands temperature 200 C.

Mechanism material: Stainless steel Aisi 304.

ROHS compliance: These mechanisms are ROHS compliant.

Identification: Model and date of manufacture are stamped on each mechanism. When equipped with a thermal bulb, it has its own color identification (see

the data sheets of the thermal bulbs).

Salt spray resistance: According to ISO 9227-2012, subjected to a mist formed of 20% by weight of sodium chloride in distilled water, at 35°C for 5 days (120h),

the mechanisms retain their aptitude for the function.

Main references

| Temperature | Length A | Reference | Length A | Reference |

| Without thermal bulb | 25mm | 51A2006215PE0000 | 30mm | 51A2006215PF0000 |

| 57°C (135°F) | 25mm | 51A20062152E0570 | 30mm | 51A20062152F0570 |

| 68°C (155°F) | 25mm | 51A20062152E0680 | 30mm | 51A20062152F0680 |

| 79°C (174°F) | 25mm | 51A20062152E0790 | 30mm | 51A20062152F0790 |

| 93°C (199°F) | 25mm | 51A20062152E0930 | 30mm | 51A20062152F0930 |

| 141°C (286°F) | 25mm | 51A20062152E1410 | 30mm | 51A20062152F1410 |

Downloads

Datasheets

Drawings

Related products

FIRE DETECTION

FIRE DETECTION

Technical informations associated to this product

-

Historical and technical introduction of fusible alloys and fire safety fusible links

The earliest known piece made of lead and tin alloy seems to be an Egyptian vase found in Abydos, dated around 1400 BC. During the Roman Empire, lead was used for the construction of water pipes. Melting at 325°C, -

Historical introduction to temperature measurement

The temperature measurement was preceded by a long period, throughout the 18th century, when first empirically and then gradually more accurately, have been developed measurement scales, were discovered fixed points for the calibration of these scales, and all physical variations related to temperature change: thermal expansion of gases, liquids, metals and other solids, liquefaction temperatures, boiling temperature, magnetism, thermoelectricity, just to give a few. -

Temperature sensing principles

The bimetal strip is formed by two co-laminated metal. One has a high coefficient of expansion, the othera lower or zero. When the strip is heated, it bends proportionally to the temperature. These bimetal blades are generally flat and fixed at one end. But they can be wound in a spiral shape, although this arrangement most often used in the construction of thermometers.